Manufacturing

Web App, SAP, Automation

Enterprise

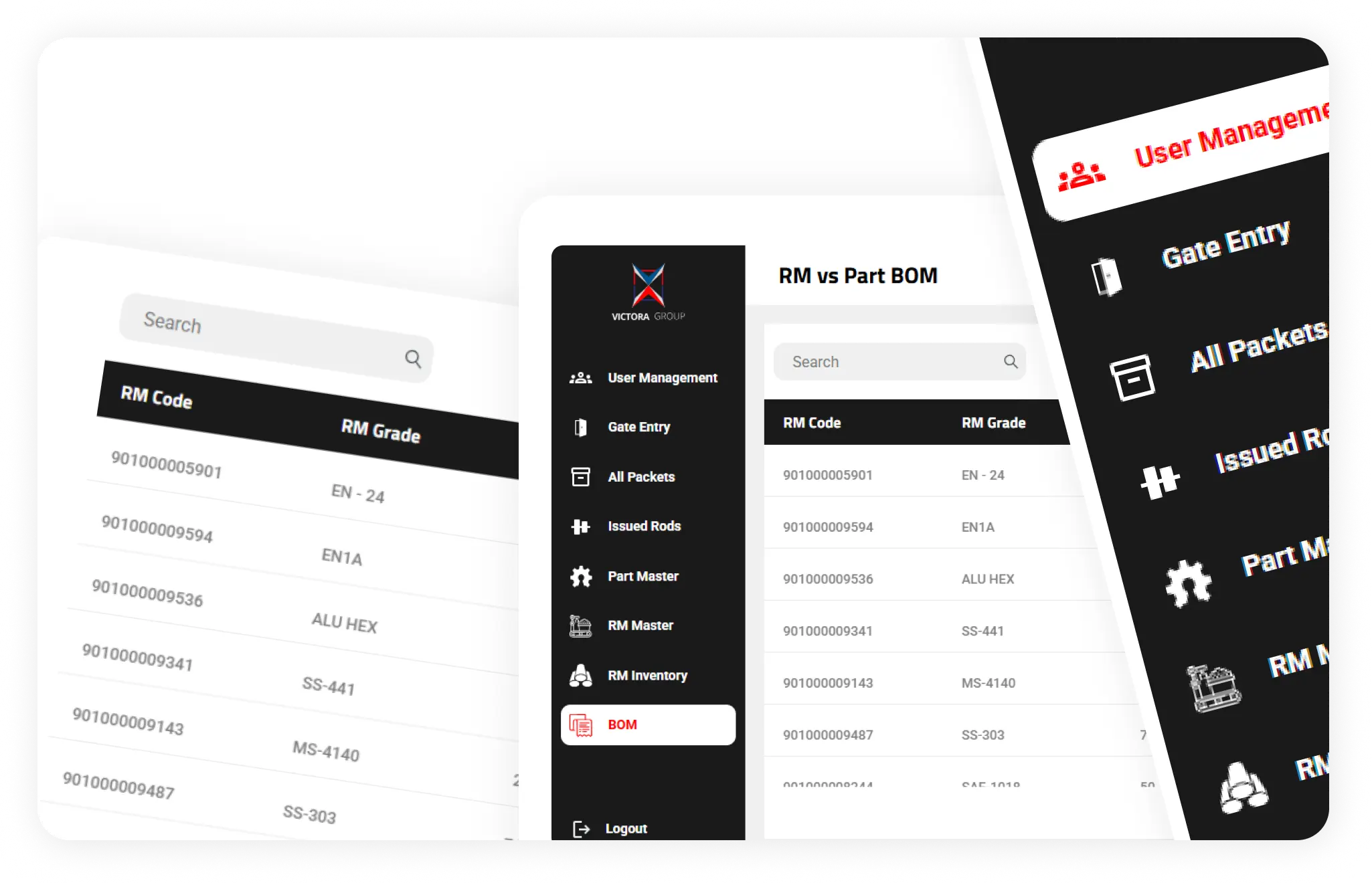

Victora Auto was willing to develop automotive inventory management software that can help them track bins right from gate to production. They wanted to get rid of manual tracking which affected operational accuracy and accountability due to data inconsistencies, delays, and limited visibility into inventories.

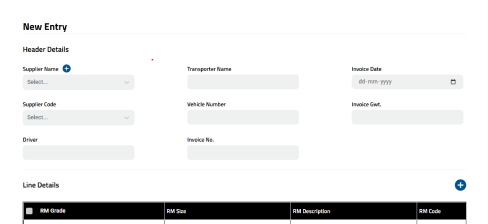

Captures material details at the point of entry with vehicle, supplier, invoice, and transporter data.

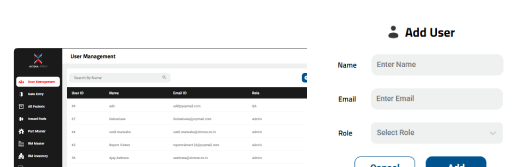

Separates user roles for Admins, Gate Entry Operators, and QA Providers to ensure secure access and workflow management.

Automates generation and scanning of QR codes for fast and accurate bin identification and data handling.

Reflects any status changes, like QA approval/rejection immediately in the Victora Auto Bin Tracking System.

Tracks the status of automotive components, including quality approvals with reason tagging.

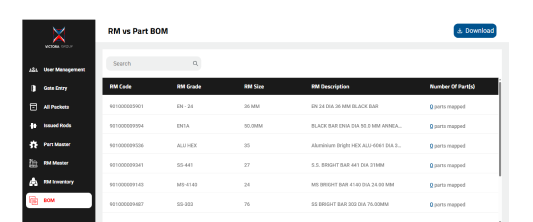

Helps in quick data access by finding records on multiple parameters using Smart Factory Inventory Solutions

Ensures seamless master data retrieval and alignment with enterprise systems by connecting the bin tracking system with SAP backend.

Enhanced material tracking using manufacturing traceability solution for Victora.

Reduced manual errors through digital inventory tracking for Vicora Auto.

Improved quality control by enabling real-time QA status tracking and decision logging.

Strengthened inventory accountability and audit-readiness with structured digital records.

Streamlined gate entry management for automotive plants with clear role-based workflows.

The InnovationM-Victora collaboration led to the development of a customized bin tracking system to monitor inventory bins right from entrance to production. This resulted in greater efficiency, transparency, and operational control, supporting the company’s commitment to smart factory inventory solutions.